Applicable industry

Automotive

Ningban’s lanthanide nodulant used in automotive brake brackets

Casting’s specification

Casting’s specification

Weight: 3.2 kg

Material: FCD450

Spheroidization rate: > 80

Mechanical property: with a tensile strength of above 450Mpa

Experimental purpose: to learn about the applicability of lanthanide spheroidized alloy (La series nodulizers)in special structural brackets (thin-walled castings) and its contribution to performance and reverse chill improvement.

Experimental process:

1. Spheroidized alloy

|

Specimen |

Granularity |

Alloy content |

||||

|

RE |

Si |

Ca |

Al |

Mg |

||

|

NBCH-5.5(HC) |

5-25MM |

0.75% |

45.57% |

2.14% |

0.40% |

5.62% |

2. The composition of raw molten iron in the furnace is confirmed as follows: (%)

|

C |

Si |

S |

Mn |

P |

Al |

Ce |

Others |

|

3.7372 |

2.2850 |

0.0087 |

0.1766 |

0.0253 |

0.0023 |

0.0038 |

Trace |

|

3.7151 |

2.3172 |

0.0078 |

0.1413 |

0.0258 |

0.0017 |

0.0036 |

Trace |

Spheroidization process

Due to the smaller H/D ratio, the reaction in the ladle is more intense, and the Mg absorption rate is lower, standing at about 64%.

Confirmation of the spheroidization process: Based on the properties of NBCH-5.5(HC) alloy the wall thickness of the cast iron product, the S content in the raw molten iron, and the intended spheroidization degree of the bracket, the dosage is as follows:

3. Experimental data:

|

C |

Si |

S |

Mn |

P |

Al |

Ce |

Mg |

|

3.43-3.60% |

2.70-2.88% |

0.006-0.011% |

0.15-0.18% |

0.023-0.026% |

0.008-0.009% |

0.004-0.006 |

0.031-0.034% |

|

3.41-3.52% |

2.82-2.95% |

0.006-0.009% |

0.15-0.16% |

0.024-0.025% |

0.008-0.009% |

0.004-0.006 |

0.031-0.035% |

|

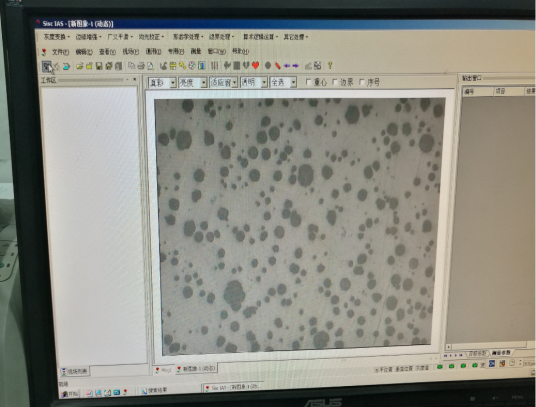

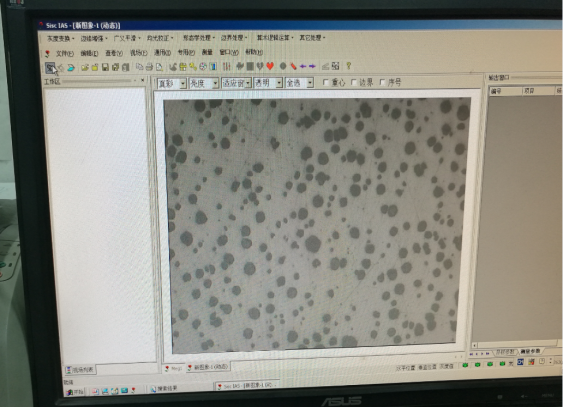

Spheroidization rate:above 90%;Qualified |

Matrix structure: no carbide; dense matrix without obvious shrinkage porosity; Specific module 2 slightly shrank: Qualified |

||||||

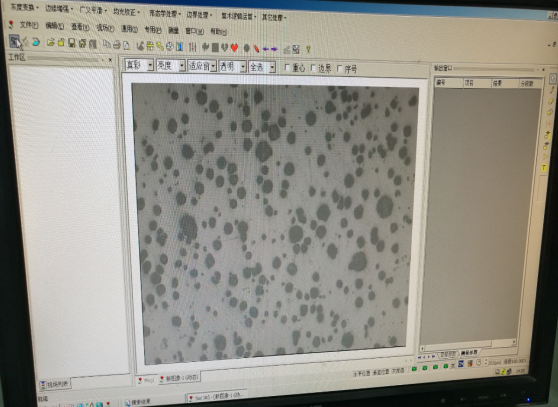

Metallograph and performance

Specimen metallography

II.Structure and mechanical properties

|

Part

|

Spheroidization rate

|

Mechanical properties

|

Test lug’s mechanical properties |

|

|

Tensile strength |

Percentage of extension |

|||

|

Thin beam |

>90% |

Qualified |

490.044 |

11.5714 |

-

Social Responsibility