Applicable industry

Construction machinery

Ningban’s nodulant and inoculant used in parts of construction machines

Process data

一、Standard of nodulizer

Granularity:3 ~ 20mm

| Ingredients | Si | Mg | Ca | RE | Al | |||||||

| Contents(%) | 42.0~ 50.0 | 6.10~7.00 | 2.00~2.80 | 2.00~2.80 | < 1.20 | |||||||

二、Test

1.Material:FCD500

2.TP conditions

| NO. | 1 | 2 | 3 | 4 | 5 | |||

| TP spectrum testing sample (min) | 1 | 6 | 9 | 15 | 17 | |||

| TP test block casting time (min) | 1 | 6 | 9 | 15 | 17 | |||

| ※Sampling: Calculated starts from the completion the spheroidizing reaction | ||||||||

3.Test items:vary with the reaction time:①Using TP spectrum test samples to confirm the content change of residual Mg of molten iron.

②Using TP test blocks to identify the spheroidizing or inoculation fade status.

4.Inoculation method:0.5%

5.Molten iron outlet temperature:1490℃

6.Spheroidizing reaction time:1ˊ44〞

三、Test item

1.Ingredients:

| Spectrum TP code | Sampling time | Kg Molten iron qty. | C | Si | Mn | P | S | Mg | Ce | Cu | Ti | Sn | ||

| Kg | % | % | % | % | % | % | % | % | % | % | ||||

| YT | 3.72 | 1.82 | 0.26 | 0.028 | 0.0190 | 0.002 | 0.08 | 0.0126 | 0.009 | |||||

| CT-1 | 0:01 | 2230 | 0.021 | 0.0107 | 0.0475 | 0.014 | 0.36 | 0.0110 | 0.007 | |||||

| CT-2 | 0:06 | 660 | 0.020 | 0.0104 | 0.0465 | 0.013 | 0.36 | 0.0105 | 0.007 | |||||

| CT-3 | 0:09 | 0.020 | 0.0115 | 0.0445 | 0.013 | 0.35 | 0.0115 | 0.007 | ||||||

| CT-4 | 0:15 | 0.021 | 0.0112 | 0.0426 | 0.012 | 0.36 | 0.0104 | 0.008 | ||||||

| CT-5 | 0:17 | 0.021 | 0.0120 | 0.0417 | 0.010 | 0.35 | 0.0100 | 0.006 | ||||||

2.TP's mechanical properties and structure

| NO. | TP code | Time | Kg Molten iron qty. | ResidualMg | Yielding | σb | δ | HB | graphite ball qty. | Graphite ball diameter | nodularity | Pearlitic rate | ||

| min | Kg | % | N/mm2 | N/mm2 | % | n/mm2 | μm | % | % | |||||

| ≥320 | ≥500 | ≥7 | 170~230 | ≥70 | ≥30 | |||||||||

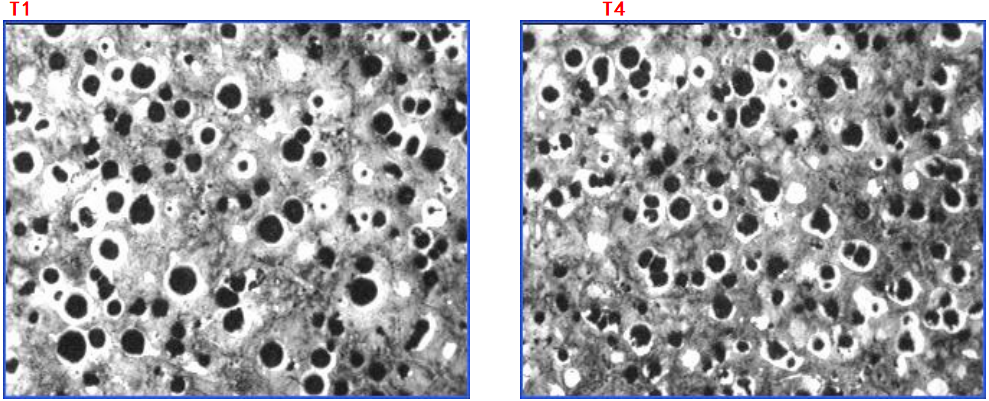

| (1) | T1 | 0:01 | 2230 | 0.0475 | 434.0 | 725.5 | 8.0 | 228.0 | 97.2 | 49.6 | 96.5 | 78.3 | ||

| (2) | T2 | 0:06 | 660 | 0.0465 | 445.5 | 715.4 | 8.2 | 226.0 | 98.6 | 48.7 | 95.8 | 77.6 | ||

| (3) | T3 | 0:09 | 0.0445 | 424.6 | 703.8 | 8.4 | 226.0 | 100.8 | 45.7 | 96.3 | 75.1 | |||

| (4) | T4 | 0:14 | 0.0426 | 417.1 | 685.3 | 8.4 | 224.0 | 103.8 | 44.3 | 96.0 | 72.8 | |||

| (5) | T5 | 0:17 | 0.0417 | 420.6 | 678.9 | 9.0 | 226.0 | 109.4 | 43.8 | 93.2 | 70.4 | |||

3.Microstructure(100X)

四、Conclusion

| Date | Nodulizer granularity distribution | Spheroidizing reaction | Fe resid | Duration | Mg residue change | TP nodularity | Graphite form | TP graphite ball qty. |

| 3~20mm | 50〞~2min | Kg | min | 0.03~0.05% | ≥70% | n/mm2 | ||

| 8828 | 10~15mm居多 | 1′44〞 | 660 | 17 | 0.0475→0.0417 (△0.0058%) |

93.2~96.5 | 球状 | 95~120 |

| The test production had a good spheroidizing reaction with the granularity distribution mainly between 10~15mm, and the graphite still kept the spheroidal form after 17 minitues. | ||||||||

-

Social Responsibility