Applicable industry

Shipbuilding

The thick and large section ductile iron uses the special nodulating agent and the silicon rare earth inoculant

Casting’s specification

Casting weight: 14 tons

Material: QT400-18L

Spheroidization rate: > 80%

Mechanical properties: Tensile strength 350-400Mpa

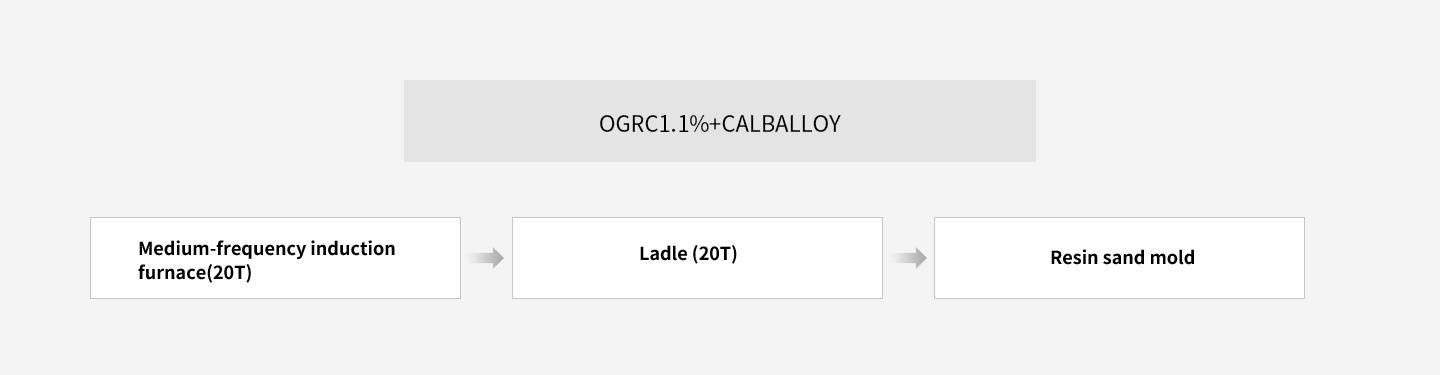

Process and molten iron’s composition

The raw materials used in the production of low-temperature ductile iron shall qualify stringent composition control - with a low content of trace alloying elements, the Si content of 2.1-2.2% and the Mn content of below 0.15% (Mn<0.15%).

Raw molten iron’s composition:

| C | Si | S | Mn | P | AI |

| 3.7700 | 1.3100 | 0.0100 | 0.1300 | 0.0280 |

Product’s composition:

|

No. |

C |

Si |

S |

Mn |

P |

Al |

Mg |

|

1# |

3.72 |

2.07 |

0.004 |

0.14 |

0.028 |

/ |

0.031 |

|

2# |

3.7100 |

2.0500 |

0.0040 |

0.1400 |

0.0280 |

/ |

0.033 |

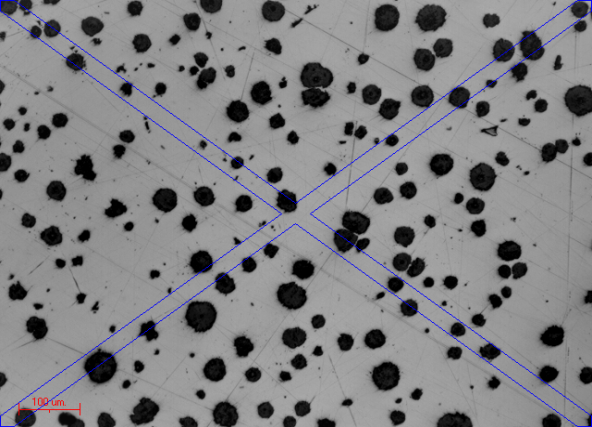

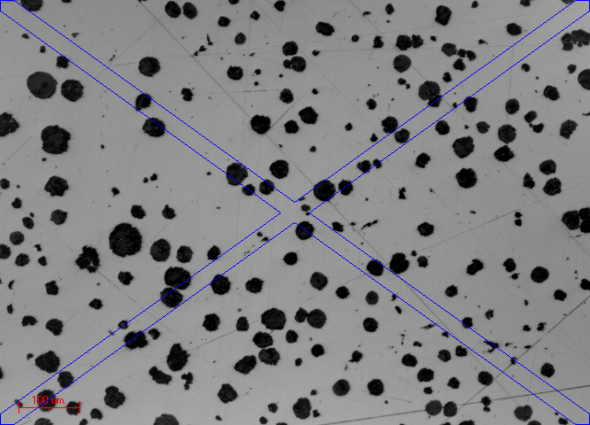

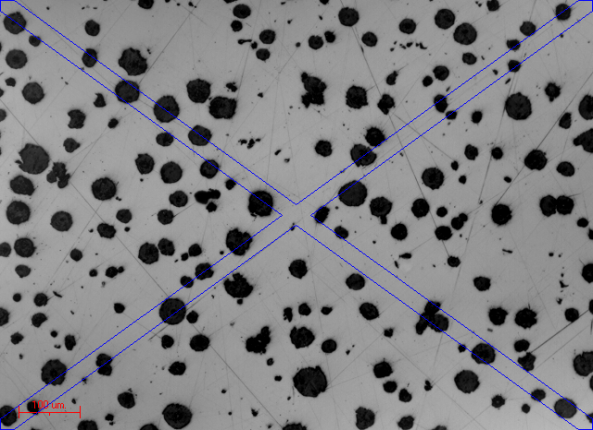

Test lug’s metallographs Metallography microstructure of cast sample

Structure and mechanical properties

|

No. |

Item |

1# |

2# |

Comparison |

|

1 |

Mechanical properties |

Tensile strength/Yield strength/ Elongation percentage (fluctuation range for regular products) |

The mechanical properties of products tested are within the fluctuation range for regular products, and qualify the requirements of customers. |

|

|

|

|

382/242/23/132 |

386/244/18.5/133 |

|

|

2 |

Spheroidization rate |

Spheroidization rate (range) |

The spheroidization rate is 90%-98%, and meet the requirements of customers. |

|

|

|

|

90%-98% |

90%-98% |

|

|

3 |

-40℃ impact |

Low temperature impact value (fluctuation range for regular products) |

The low temperature impact values of products tested are within the fluctuation range for regular products, and qualify the requirements of customers. |

|

-

Social Responsibility